Hey, I’ve got an idea. How about we reduce our carbon footprint just in case it helps with that global warming thing. I propose we take a tiny little bit of that foul crude oil and use it against itself – sort of like Darth Vader turning on the Rebel Alliance. We’ll process just a tiny bit of it into stuff that big-time reduces the use of the stuff remaining in the ground. I know that sounds like crazy magic, but I think we can do it – use a tiny bit now so that we use a lot less later. BRILLIANT!

We’ll call it foam insulation.

I like foam insulation and it really does that magical thing. Some people think it’s the devil. I blame Dustin Hoffman for that[1].

[1] In 1967 Hoffman starred in a movie called The Graduate. It’s a classic story of dysfunctional relationships. The most memorable line from the movie is when middle aged, career man Mr. McGuire gives the young, confused Benjamin Braddock (Hoffman) career advice: “I have one word for you: PLASTICS!” Plastics instantly became uncool for an entire generation.

Anyway, I think I bought a piece-of-shit spa cover, but, it turns out that’s all they sell. Ultimately, my spa cover, and everyone’s spa cover gets waterlogged and the question is why, what should I learn from that, how can I prevent it and how can I extend that knowledge into building designs.

First things first, hot tub covers are insulated. Typically, they have a modest looking vinyl cover over a sealed plastic bag and inside that plastic bag is a slab of tapered Expanded Polystyrene (EPS) insulation. The underside of the inside of the cover is typically open mesh. The vinyl cover is waterproof, so, the water in the waterlogged insulation isn’t coming from the sky, it’s coming from the water in the tub. The vinyl cover is really just there to keep the UV radiation off the interior plastic bag and to keep rain water out of the tub.

The water is usually around 103oF and is sanitized with some sort of bromine stuff. That bromine stuff, BTW, always has some chlorine in it. They tell you it’s all bromine, but, it’s not and that’s just the way chemistry is[1]. Purity is relative.

[1] Look at the periodic table, the elements immediately above and below the one you’re interested in – bromine in this case – always sneak in as replacements. They are like party crashers – so adept at fitting in that they’re always there. In the same way, there’s always some strontium in your bones instead of calcium and always some magnesium in your lime mortar.

Let’s start with that insulation. It’s there because without it the spa would use tons more energy to keep itself hot. Without the cover the cost to run the spa would skyrocket and it would be wasteful. The spa needs an insulated cover. It’s EPS (Expanded PolyStyrene) because that’s the variety of rigid insulation that can be created in the shape needed – pitched – at a reasonable price. The covers are always pitched so that rain water will easily run off. Usually the pitch is about 2” across 48” – plenty of pitch. Other insulations, like XPS (eXpanded PolyStyrene) and closed cell polyurethane foam can be shaped but only in molds. That molding process is much more expensive and doesn’t always work out so perfectly. EPS is the go-to insulation when you need shapes. Check out some of the work done by Symmetry International in Rhode Island[1]. They have been using EPS to make every variety of crazy shaped thing since the early 80’s. Even this sort of thing:

[1] www.symmetryproducts.com

Yeah, those M&M’s are made with EPS insulation.

Every sort of claim is made about rigid foam insulation’s inability to absorb water. In short, just about everyone says that it does not absorb water. If you examine all the manufacturer’s literature you would have to conclude the same thing – effectively, EPS and XPS insulation don’t absorb water.[1] Same for closed cell spray polyurethane foam insulation – effectively, no water absorption. You can review all the relevant ASTM tests) and review all the manufacturer’s published ASTM test results and, yup, none of them really absorb much water at all. A few % by volume, max and that tiny % gets even smaller as the density of the foam (compressive strength) goes up. EPS seems to absorb more than XPS, but, it’s still a tiny percentage. Even better, the loss in thermal resistance isn’t so horrible at these ASTM test maximums: about 15% loss for EPS and even less for XPS. No big deal, you can design around that, just add some thickness.

[1] The other most common rigid insulation, polyisocyanurate, doesn’t absorb so much water either, but, its chemistry is such that it’s hydrophilic – it likes water and actively sucks it up when possible and even pulls it out of the air.

Son-of-a-bitch, those ASTM tests aren’t worth jack-shit[1] in some real world applications. Hot tub covers are one of those real world conditions. Dock floats, small boat shell filler and roof membranes that are too flat are others. The testing usually runs for some limited duration, like 24 hours, and the real world applications runs for like 24,000 hours. Turns out that time difference makes a difference. The real world can be brutal compared to the laboratory and, the difference between 2% or 3% water absorption and 8% water absorption is enough to make a spa cover so heavy it becomes difficult to lift and has almost no insulating value.

[1] Jack-shit is the diminutive form of shit in the same way that a jack-stud is a shorter stud and the jack-bowl is the little white ball in Lawn Bowling. So, jack-shit is like a little, worthless shit. About the same as fuck-all, although I find that one harder to explain.

Here’s the thing, closed cell foam isn’t really closed cell foam. It’s MOSTLY closed cell foam. Like 90+ % if everything goes well during manufacturing. And, the polymers used to make those foams – polystyrene and polyurethane – aren’t entirely impervious to water all by themselves. Water vapor can diffuse straight through a film of polystyrene or a film of polyurethane. On top of that, EPS rigid foam is made by fusing tiny balls of expanded polystyrene foam together, so, there’s always little pockets of free space between those tiny spheres. It’s the coffee cup insulation, you can see those little spaces and it’s obvious that water vapor moves through that foam.

One last thing about those spa covers – that plastic bag wrapping the foam. I don’t want to call it useless, but, it’s darn near useless. I don’t know what it’s made of, but, it’s probably polyethylene. That’s the same stuff typically specified for the vapor barrier below concrete slabs on grade. Here’s a photo of a vapor barrier below a basement floor (the yellow plastic around the slab edges) and a photo of the sheet plastic in my spa cover:

Same stuff (sort of), different color and thickness.

Polyethylene is a pretty good vapor barrier and, normally, it would be a reasonably good way to protect that core of insulation from water vapor. However, it’s no match for the conditions immediately above the hot tub water surface. It’s a constant 103oF and 100% relative humidity. Oh, and the air is thick with high energy bromine and chlorine compounds. That’s like the worst possible weather day you would ever experience on the equator, in the Amazon jungle inside a bleach factory. You can’t even use the regular psychrometric chart to figure out the water vapor pressure in that location. I had to use the steam tables from my 1983 vintage Chemical Rubber Company Handbook to get that info. Anyway, when you do that, you find that the vapor pressure is about equal to the force of a 240 MPH wind[1]. And that’s before the bromine and chlorine soften things up. That skinny sheet of plastic is like a speed bump in front of a speeding tank.

[1] Point of reference: the vapor pressure below your basement slab is equivalent to a wind speed of about 37 MPH.

So, what happens? The high energy water vapor immediately above the water surface in the hot tub diffuses through the sheet plastic around the rigid insulation then either diffuses through or around the rigid insulation. When it gets to the top surface of the insulation it cools down and condenses. (Reminder, that air immediately above the water in the hot tub will condense at any temperature less than 103oF.) Now there’s liquid water inside the sheet plastic wrap , it’s in direct contact with the EPS insulation and it can’t escape. This goes on 24 hours per day for hundreds of days. The liquid water slowly saturates the insulation from the top surface down. It does this by absorption into the plastic itself, adsorption on the surface of the plastic in every location that the vapor can get to (which is all the not-closed cells, all the free area gaps and all the truly closed cells that now have water vapor inside them since it diffused straight through the plastic film of the bubble) and by capillary condensation. Eventually it gets it up to about 20% water, by volume. That’s about a 60 pound lift for each half of the cover. Heavier than I want to deal with and the insulating value is gone. The spa cover is now officially useless. I don’t know what the upper limit of water absorption by volume is, but, I would guess it’s 80+%, given the right conditions (which might be hot, chlorinated water for a long, long, long time).

Higher density EPS insulation might hold out a little longer, and the ultimate water content might be a little lower, but, in the end, the same thing would happen. Same for XPS and same for closed cell spray polyurethane foam. They all suffer from the same problem, just to different degrees.

A better vapor barrier around the insulation would help – like those metallic coated coffee and electronics package things.

They seem to have about one tenth the vapor transmission rate vs. normal polyethylene. But they have problems too. First, they’re more expensive. Second, you’ve still got high energy bromine and chlorine compounds mucking up the works. Third, their vapor transmission rate isn’t zero – given enough time, plenty of water will get through, and then it’s got nowhere to go. A thick version of those metalized coffee ground bags would probably help, but, eventually it will also fail.

In the end, the typical spa cover is about the same as lots of materials we install on buildings: they are the best choice for a variety of reasons – economics being the greatest – and should not be expected to last so long. That’s like asphalt roof shingles, exterior paint and most finish flooring. It’s the best alternative given all the choices.

So, what’s this mean for buildings? Keep your insulation dry, because, unlike spa covers, replacing your insulation in a building is usually major surgery. If it’s going to be in a place where it may be in contact with liquid water give that liquid water a way to drain out and go away. If it’s possible to give one side of the insulation a way to vent water vapor away that would also help. Once again, water is the problem. Get rid of the water and there is no problem.

Above grade this sort of saturated rigid insulation problem is rare. The Space Shuttle external fuel tank problems may have been one of those, but, NASA’s not giving up those secrets[1]. Roof membranes made with closed cell spray polyurethane foam that are too flat and left unprotected can have this problem. Maybe a stupid detail where an edge of rigid insulation sits on a surface that holds liquid water would also be a problem – like an upside down z-furring strip in an exterior wall. Of course, that would be stupid.

[1] Read BSI-021: Thermodynamics, It’s Not Rocket Science by Dr. Joe Lstiburek if you want to learn more about closed cell foam, the space shuttle and vapor drive. https://buildingscience.com/documents/insights/bsi-021-thermodynamics-its-not-rocket-science.

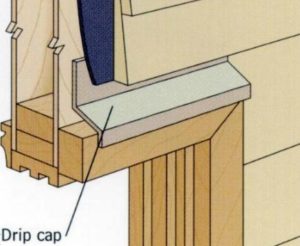

Cap and base flashings, however, are an area that deserve a little extra attention. For an exterior insulated building it is not unusual for rigid insulation to land directly on cap and base flashing. If that flashing is dead flat or back-pitched then they could hold a small puddle of water and that water could saturate the insulation immediately adjacent. This is really a non-issue since that water is much more likely to evaporate into the surrounding air, but, a tiny pitch to the exterior on that flashing is always the right thing to do. Don’t give water a place to hang around – get rid of it as fast as possible.

Subgrade insulation of a foundation is a more likely place for this sort of saturation problem to happen. The solution is still the same – drainage – but, sometimes drainage below grade is difficult. I prefer to locate that drainage on the exterior side of the insulation so that it’s between the earth fill and the insulation, like this:

Some people reverse that order. I think they’re worried that the drainage mat can’t take the abuse that happens during backfill. That’s silly, it was designed for that, and they’re putting the insulation in a riskier position.

Subgrade insulation below footings is probably the most difficult to protect from this sort of saturation problem. Of course, this only occurs in high-performance buildings and freezer buildings, but, insulation below footings is a real thing and it’s not at all difficult to get insulation that is strong enough for this location[1]. If you’re willing to pay, compressive strength is not an issue.Anyway, in these locations, again, drainage is the only solution. If the house is in a swamp, plan on a lot of pumping.

[1] Think about this, a typical house is designed assuming two ton soil bearing capacity. That’s 4,000 lbs/SF. That’s only 28 PSI. The typical XPS insulation you buy at Home Depot is 25 PSI. It’s very easy to order XPS and EPS insulation with compressive strengths up to 100 PSI and you can get it at higher values if it’s really needed, like directly below a column.

That’s about it for hot tub covers Good luck with that IR image question.

Foster

Footnotes

1 In 1967 Hoffman starred in a movie called The Graduate. It’s a classic story of dysfunctional relationships. The most memorable line from the movie is when middle aged, career man Mr. McGuire gives the young, confused Benjamin Braddock (Hoffman) career advice: “I have one word for you: PLASTICS!” Plastics instantly became uncool for an entire generation.

2 Look at the periodic table, the elements immediately above and below the one you’re interested in – bromine in this case – always sneak in as replacements. They are like party crashers – so adept at fitting in that they’re always there. In the same way, there’s always some strontium in your bones instead of calcium and always some magnesium in your lime mortar.

4 The other most common rigid insulation, polyisocyanurate, doesn’t absorb so much water either, but, its chemistry is such that it’s hydrophilic – it likes water and actively sucks it up when possible and even pulls it out of the air.

5 Jack-shit is the diminutive form of shit in the same way that a jack-stud is a shorter stud and the jack-bowl is the little white ball in Lawn Bowling. So, jack-shit is like a little, worthless shit. About the same as fuck-all, although I find that one harder to explain.

6 Point of reference: the vapor pressure below your basement slab is equivalent to a wind speed of about 37 MPH.

7 Read BSI-021: Thermodynamics, It’s Not Rocket Science by Dr. Joe Lstiburek if you want to learn more about closed cell foam, the space shuttle and vapor drive. https://buildingscience.com/documents/insights/bsi-021-thermodynamics-its-not-rocket-science.

8 Think about this, a typical house is designed assuming two ton soil bearing capacity. That’s 4,000 lbs/SF. That’s only 28 PSI. The typical XPS insulation you buy at Home Depot is 25 PSI. It’s very easy to order XPS and EPS insulation with compressive strengths up to 100 PSI and you can get it at higher values if it’s really needed, like directly below a column.