Why does tile sometimes look wet when it’s dry?

Answer:

Because it is wet.

Feels dry, acts dry. Not dry.

This is one of those SUPER irritating problems for anyone involved: owners, designers, architects, contractors, subcontractors, suppliers, insurance companies …… attorneys probably like it. It’s almost exclusive to stone tile flooring in wet areas like a shower floor, and almost exclusive to marble. Almost. And once it happens the only fixes are expensive.

Strangely, this staining rarely happened in the past – ancient Greeks, ancient Romans, old tile setters, young tile setters not so many years ago, and even the French didn’t usually experience this problem. It’s not that they didn’t have showers. Showers, more or less as we know them today have been around since about 550 BC.

Acres of beautiful stone flooring has been set in wet areas over thousands of years without this wet staining problem. Only now that we’re fancy, and modern, and have space-age materials, and YouTube videos explaining their installation is it somewhat common and seen in every variety of building – modern spec homes, modern high-rise apartments, custom homes, etc.

Some say “don’t blame the stone” but, it’s kind of the stone. It’s not that the stone is defective or that the quarries have been depleted of good stone. The stone is, more-or-less, the same as it’s ever been. And it’s always been porous and a little bit translucent. Those properties, together with water and some of our modern materials and modern assemblies are the cause of the wet stain problem. If the stone isn’t translucent, either you never see the problem or you see it for a very much shorter period of time. If the stone isn’t porous, then it’s not stone – all stone is porous to some degree.[1]

Pores in stone are sort of like drinking straws. They suck. That is, if dipped into water they will pull water in because of capillarity in the same way that water in a straw will climb upward.

![]()

If the pores are large, water can enter and leave rapidly, same like drinking straws. A large diameter 7-Eleven, Extra Grande, Slurpee straw allows you to suck up loads of soda in a great hurry. People even post videos about this: https://www.youtube.com/watch?

Try that speed chugging with a tiny cocktail straw and you might expire from dehydration before you get to the bottom of the cup. Proper engineering for cocktails, however.

Tiny pores in stone are like those tiny cocktail straws, you can’t move much fluid through them quickly. They fill and drain very slowly.

Pores in marble are very small – about one tenth of a micrometer.[3] That’s one thousand times smaller than the pointy tip of a pin. (FYI – something 1000 times smaller than me would be about 1/16” tall.) Pores in marble are really, really small.

Sort of the opposite of flow volume, large pores don’t hold water with much force, but small pores hold water tenaciously. That’s why water climbs higher in a thin straw than a wide straw. If you go through all the calculations,[4] you come up with these sorts of numbers:

Note: Capillary rise: AKA how high the water goes up in the straw

Pore size Capillary rise

¼” 0.01 inch

1/8” 0.2 inch

1 millimeter 0.6 inch

1 micrometer 584 inches

Marble pore 487 feet

1 nanometer 9 miles !

Those numbers aren’t useful for much of anything except relative comparisons. The big take-away is that small pores can do powerful things: The forces holding water in those marble pores is strong enough to pull water up to a height of 487 feet. That’s a 48-story building! Seventeen US states don’t even have a single building that tall.

So, why aren’t all marble floors with all that tremendous sucking force in every shower stall totally saturated with water and looking wet? Because those pores are so small and small pores can’t move liquid in and out with any speed. The force is enormous but the fluid movement into those pores is very slow, because they are so small.[5] If you pour water over a translucent marble and then wipe it off it will suck up almost nothing (and that “almost” is such a low number that you wouldn’t even be able to measure it). There just isn’t enough time for the water to wet the interior of the stone. However, if you dip that marble into a puddle of water and leave it alone for some time it will eventually suck that water into its pores. It will look wet because it is wet in its pores. Same sort of thing for lots of other building materials, BTW, like brick, mortar, stucco, concrete, and etc. – anything that’s porous.

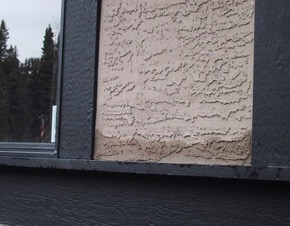

And that’s how the Romans and Greeks and all those old, dead tile setters prevented wet-stain problems. They didn’t let their marble sit in a puddle of water. They set the stone in a thick, very porous setting bed – sometimes just sand, sometimes a sand-lime cement mud bed, never a non-porous material – and they allowed that very porous setting bed to drain out easily. That’s called the full bed method. Basically, all six sides of those stones are dry most of the time and never experience water for long enough to allow any significant water uptake in the pores. And, when they’re not being wet from the top they’re drying out. The stone stays dry inside and out.

We still build that full bed assembly today in many wet floor locations. It’s a well-documented, industry standard installation method – see, for example, the Dimension Stone Design Manual, Chapter 16. Pitch the sub-floor (1/4” per LF min.) waterproof that pitch (no wrinkles, no puddles, no mini-dams, etc.), lots of sand and not much white cement in the mud bed, two-stage drain with weep holes protected from clogging. Awesome!

That sort of assembly allows water that gets into the grout between the stones or the mud bed below the stones to fall to the waterproofing and drain out. The force of gravity pulling the liquid water down through the porous grout and mud setting bed moves the greater volume of water away from the porous stone faster than the porous stone can pull that same liquid water into itself. That imbalance of fluid volume flow rates keeps the stone dry and without wet stains.

So, what did we screw up as we got modern? We forgot the fundamentals. We forgot that if the marble sits in a puddle, it has plenty of time to suck up water and when it does, it looks wet, because it is wet. And then you’re properly screwed. You’re properly screwed because those pores hold that water with great tenacity, and it takes a long, long time to dry out and return to its original color. Worse, it may never come back to its original color if that water reacts with various minerals in the stone or moves salts around within the pores. Water is mischievous, and given enough time, will screw everything up.

It’s not unusual for manufacturers to modify their products over time for cost reduction and marketing advantage. Usually, they keep doing this until the product is no longer fit for its purpose. And then they reverse that one last modification (maybe). Same for almost everything in life, including shower floors. For the wet stain stone problem, thinset mortar was that modification that broke the camel’s back.

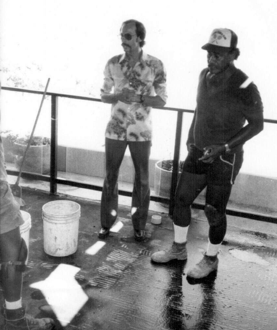

Thinset mortars were introduced into the construction market in the 1950’s by a chemical engineer who wore hip clothing and tinted glasses:

That thinset allowed tile and stone to be set in a thin bed of mortar rather than a thick bed of mortar.[6] It has saved lots of space, lots of time, and lots of money for developers and builders. We can now build tile floors and walls that are thin, not thick. That’s a big deal and that guy deserves to be able to wear any crazy shirt he wants.

But everything has pros and cons. One of the downsides of that thinset mortar is that it is not as porous as those old sand-cement setting beds. In fact, sometimes it’s pretty dam-near waterproof. So, when there’s a little imperfection or crack between the edge of a stone tile and the surrounding grout, water will drop down past the exposed surface of the stone and then just sit there until it eventually gets pulled into the pores of the stone.

So, if the installation contractor is super careful, follows every industry guideline, and follows every material manufacturer’s installation instruction you have a chance for success because no water will get past the exposed surface of the stone. Good luck with that – there’s always a defect somewhere.

What to do to minimize problems brought about by inevitable defects: increase the budget, use space-age materials, and be super careful. 100% solids epoxy thinset mortars and 100% solids epoxy grout – if they’re compatible with the stone (meaning, they don’t stain the stone themselves) – can be helpful in avoiding the wet staining problem. Those materials stick to the stone better and are more flexible, so, there will be less (maybe even no) cracks at the stone edges and those materials. On top of that, they are non-porous, so they don’t hold any water. Adding a drainage mat below the thinset adhesive and draining it into the lower weep holes of a two stage drain can also help. Basically, with those materials you won’t have any puddles for the stone to sit in. You will only have water on the exposed surface of the stone and that water just doesn’t have enough time to get pulled into the stone in any volume to cause it to look wet stained. In short, the stone remains dry.

So, either build it like you’re in ancient Rome or build it with only the most advanced (and expensive, and difficult) modern materials. No in between. And, keep in mind, there are lots of other ways to screw up a natural stone installation. This one tiny topic – wet staining – is just one small corner of the natural stone story.

If you want to know more about the specifics of exactly how to build those wet floors properly check out this installers work.

[1] Except for obsidian, tektites, fulgurite, and pure crystals like quartz or diamond. Good luck finding floor tiles made from pure blocks of any of those.

[2] Warning: speed drinking an ice-cold drink will cause serious sphenopalatine ganglioneuralgia – brain freeze. Proceed with caution. However, it is a lot of fun to watch other people do it.

[3] There’s a lot of variation in pore size. That’s the number I’m going with today.

[4] That’s a mathematical approximation of reality under ideal conditions, with ideal material, and distilled water, and every other non-real-world condition.

[5] Not that you need to know but, the volume of fluid moving through a round pipe is proportional to the fourth power of its radius. So, 48 times more fluid will move through a 1” pipe versus a ½” pipe, all other things being equal. But pores aren’t pipes, so that Hagen-Poisuille equation and the Reynolds Number are just about useless. It’s only important to know that liquids move slower and in lower volume as pores get smaller. A little smaller is a lot slower, and etc. Also, in the real world, with porous materials, there is no such thing as “all other things being equal.”

[6] That miracle is all about water availability for the chemical reactions that happen when cement sets. A thin bed of cement and sand can’t provide enough water to the cement that creates the bond between the tile and the bed. A thin bed of “modified” Portland Cement and sand – AKA thinset – can provide enough water to the cement that creates that bond. One of the wonders of modern chemistry and not invented by the Romans.